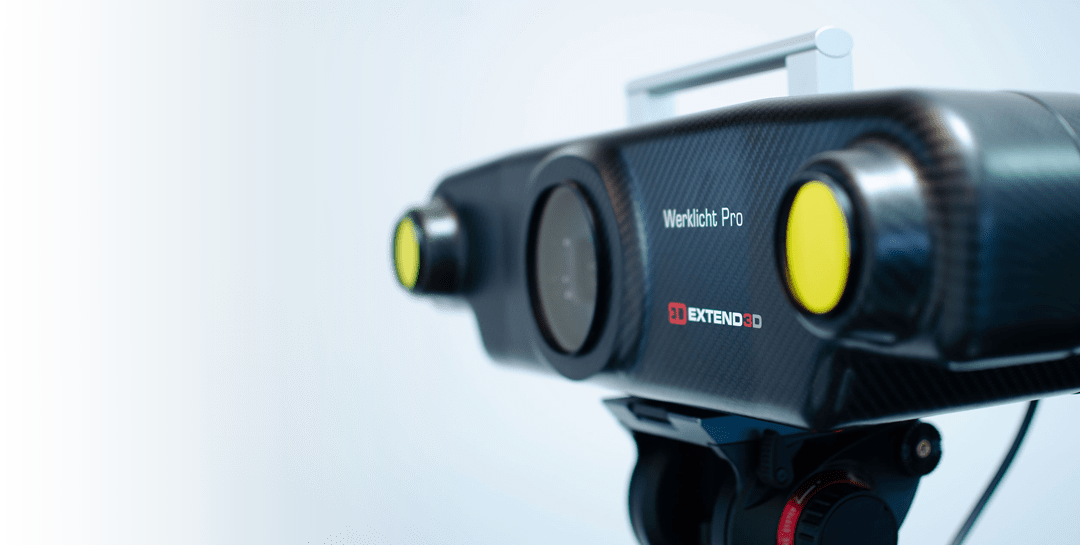

WERKLICHT PRO S

WERKLICHT Pro S brings dynamic laser projection directly to the production line. Bring digital work instructions to the moving component in the correct position. WERKLICHT Pro S was consistently designed for multi-projector installations that are firmly integrated into the production line or manufacturing cell. The synchronous operation of a freely configurable number of modular projection units allows all relevant areas to be illuminated and, in combination, even very large work volumes to be efficiently covered. As a result, complex objects can be completely processed in the shortest possible time, even in series, with the dynamic performance familiar from WERKLICHT Pro S. The economically scalable solution thus meets the special requirements of extremely short cycle times in particular.

WERKLICHT Pro S thus increases profitability even for work that previously could not be automated and thus quickly pays off for your company in several respects.

- Minimal setup time

- Automation through connection to PLC or control technology via network API

- All CAD formats

- Generic import from CSV or similar for integration with third-party systems

- Ready for IOT

- Display of positions, trims, contours directly on the part

- Intuitive operation with remote control or tracked tools

- Positioning/inspection templates become superfluous

- Time savings of up to 75% compared to classic measuring equipment

- High change flexibility

- Productive faster through intuitive visual worker guidance

- Time savings through direct highlighting of elements on the component

- No need for time-consuming localization or counting on the part

- Step-by-step instructions

- Intuitive display of assembly instructions directly on the component

- Intuitive control with remote control or tracked tools

- Automatic documentation of work steps

- PDF report with overview images and detail shots

- Export as CSV, for integration/automation with third-party systems

- Data protection compliant

- Ready for IOT

Areas of applications

The applications:

WERKLICHT Pro S is the projection solution for your production lines and cells for a wide range of applications:

- positioning tasks

- Assembly support

- Quality assurance

- Fast identification of individual features

- Support of manual workstations

- Completeness check

- … and much more!

More information about WERKLICHT Pro S

Technical details

SETTING UP THE SYSTEM:

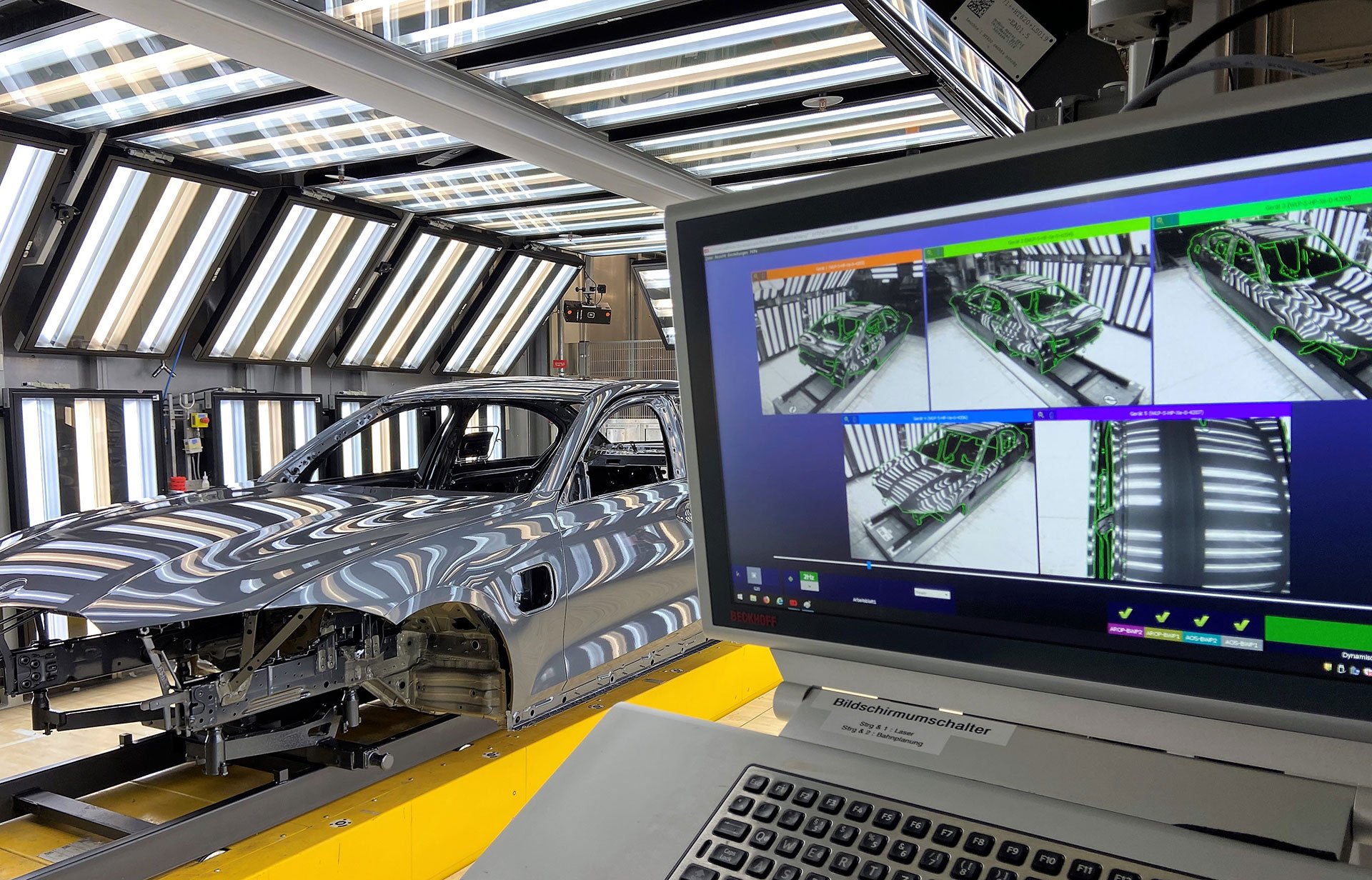

First, the CAD data of the component is imported into the EXTEND3D software for this purpose. Then, so-called targets are placed on the component in order to be able to align to the component or vehicle coordinate system. If rule geometries for RPS alignments are available, these can also be taken over and referenced.

This completes the setup and all geometries such as surfaces, edges as well as bolt and rivet positions can be displayed directly on the part, simultaneously if necessary. Typically, WERKLICHT is set up in less than 10 minutes so that your manufacturing or assembly staff can start working.

DYNAMIC REFERENCING:

If the WERKLICHT projector or component is moved, the projection automatically adjusts to the changed position. This makes WERKLICHT highly mobile and very flexible to use – the decisive advantage over conventional laser projectors.

ADAPTIVE REFERENCING:

If there are deviations between the real component and the CAD data, WERKLICHT compensates for these deviations and adapts its projection to the actual component surface.