Fields of application and application scenarios of laser and video projection in industry

Dynamic video and laser projection show their strengths in various industrial areas – especially where manual processes are necessary. Particularly in complex situations, such as short cycle times, a high number of assembly steps or a large number of variants, it can greatly simplify manual work. The areas of application for our video and laser projection range from prototype construction and one-off production to quality assurance during series production, flow production and short-cycle inline processes. Wherever, for example, steel or sheet metal must be processed manually with precision and error-free assembly steps are necessary, dynamic laser and video projection saves time. At the same time, it reduces the effort required because physical positioning and inspection templates can be dispensed with. The time benefits include reduced setup and inspection times and less rework because high-precision work is performed right from the start. In addition, time-consuming searching is eliminated because the position is projected unambiguously onto the component. A particularly important application scenario: the production of many model variants with tight cycle times. In this case, the projection shows the assembler the correct positions for the respective variant – for example, for the assembly of add-on parts. Misinterpretation is hardly possible: This reduces scrap and promotes quality.

Whether individual assemblies or nearly finished products, WERKLICHT identifies assembly positions and specifies the logical assembly sequence.

For quality assurance and process control by projecting target positions or contours directly onto the component with maximum precision.

In final inspection, thanks to model-based tracking, for the highest quality in manual rework, because no critical areas are overlooked.

Digital stencils to increase production efficiency as well as quality and greatly reduce the error rate.

Digital templates projected with the help of the laser make the tacking of welded parts more precise, among other things when welding in the course of automotive prototype construction.

Flexibility and the reduction of complexity in the interior finishing of ships, in the tacking of welded parts in mechanical and plant engineering, and add-on parts in steel and rail vehicle construction.

Digital stencils or image projections directly on the outer skin facilitate the increasingly complex and demanding outer skin coatings or foiling, for example on aircraft and ships.

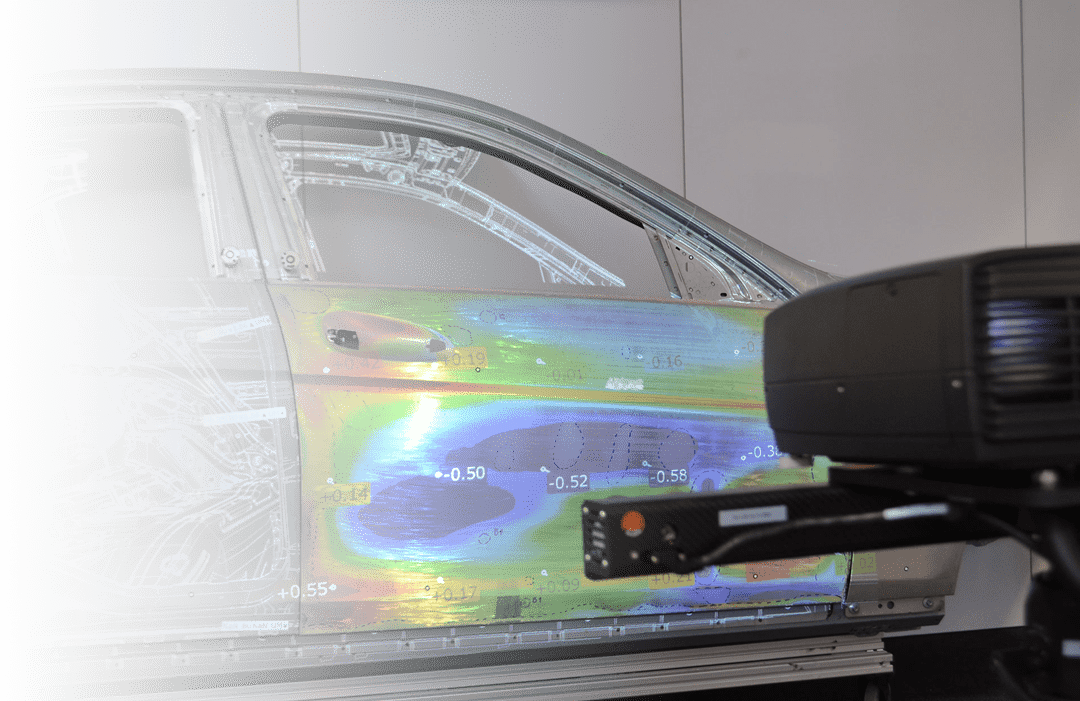

Projected measurement results on components, for example as false colors, deviation maps or point measurements. The main advantage: Coordination and intuitive visual control are quick and clear.

Laser and video projection for numerous industries

Just as CAD systems and digital component information are used in almost every branch of industry, WERKLICHT is also used in a large number of industrial sectors. Because wherever digital 3D data from CAD, measurement/simulation results or surface and texture data are used, WERKLICHT helps to turn them into reality. From unit-dependent automotive manufacturing to shipbuilding with batch size 1, the advantages of WERKLICHT can be used everywhere.

Why video and laser projection from EXTEND3D?

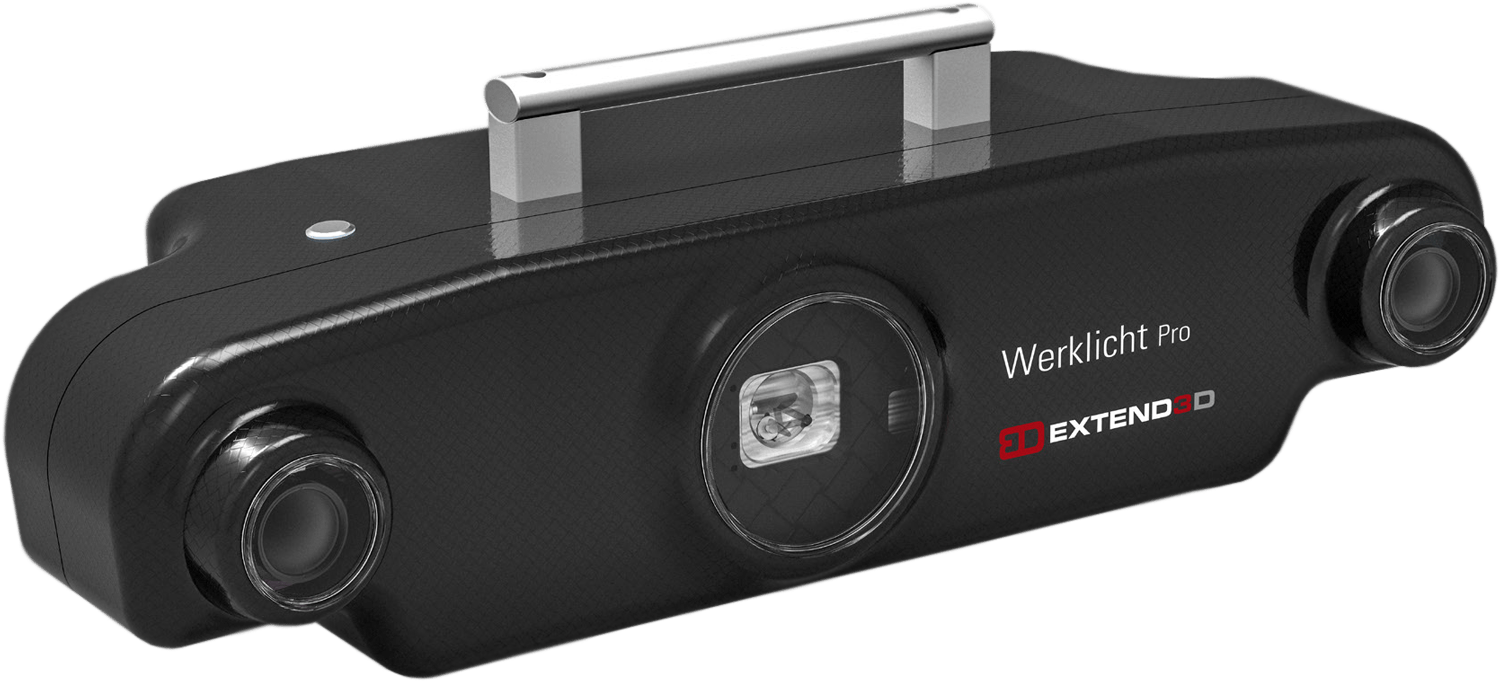

Solutions from EXTEND3D aim to provide optimal support for production, assembly, quality assurance and rework. The solutions lead to higher productivity thanks to intuitive worker guidance. The system is easy to set up, and quickly ready for use. The integrated OPC-UA interface is part of all products and enables integration into plants and synchronization with conveyor technology. Projection contents are then displayed fully automatically as soon as a component is conveyed into the relevant area. In addition, EXTEND3D offers particular flexibility in laser projection: The components can be moved or repositioned in the work process and the projection system adapts seamlessly to the new conditions thanks to dynamic referencing.

Dynamic Referencing

Dynamic referencing enables particularly high precision with the greatest possible flexibility at the same time. This means that our video and laser projectors can project the digital template onto the component at any time – regardless of whether the object or the projector is moving. The dynamics of the movement are captured by calibrated cameras and software with smart image processing algorithms and continuously calculated for the projection. This makes it possible for the laser or video image to “lock” onto the workpiece, as it were – even when it is moving. In dynamic referencing, a distinction is made between two methods: marker-based and markerless tracking. Marker-based tracking works flexibly on a wide variety of components and materials and enables high-precision digital templates while complying with specified dimensioning regulations from the construction drawing. Markerless tracking is ideal for short cycle processes.

Calibration for precise projection

For dynamic referencing to work, the video or laser projection system needs calibration. With our simple and precise solutions, we ensure high and lasting process reliability of the system. There are three calibration methods to choose from: Either the projectors are calibrated and certified in-house in our in-house calibration laboratory or the customer performs recalibration steps himself using a test board. In addition, for integrated systems, there are also automated self-calibration mechanisms in the target environment, which are performed regularly in the process. In general, our Werklicht projection systems are robust and designed for daily use on the factory floor. This is especially true for the systems in mobile use.

Highest precision even for difficult surfaces

Laser projection offers maximum precision even on uncooperative surfaces that are particularly dark or highly shiny, for example. Everything you need to know about laser projection can be found on our Wiki page.

Optimal visualization thanks to video projection

Our WERKLICHT VIDEO ensures direct transfer of the data “into practice” – onto the component in question: the engine hood, the ship’s hull or the prototype. Compared to lasers, this projection is absolutely flicker-free and as much content as required can be displayed. In addition, different colors are available for the image. For example, it can display measurement results on the workpiece in the form of false color and deviation maps or individual point measurement values. Everything you need to know about video projection can be found on our Wiki page.

Highest precision thanks to laser projection

Our WERKLICHT Pro L and WERKLICHT Pro S enable maximum precision in the manufacturing process. Our dynamic laser projection enables industry to project templates, milling lines, cutting specifications or the assembly positions of add-on parts with high precision even onto moving workpieces. Companies benefit from lower error rates, lower costs and faster processes. Learn more on our new info page: All about laser projection in industry.

WERKLICHT Pro L is a dynamic 3D laser projector for high-precision tasks in the areas of prototyping, in flow production and in series quality assurance. WERKLICHT Pro L is suitable for customized production and variant production up to series production. It is used by customers from the automotive engineering, rail vehicle construction, aerospace, marine, mechanical engineering or special vehicle construction industries, among others.

News

Contact us

If you would like a demonstration or direct advice, our sales team will be happy to assist you. Our sales staff have many years of experience in industrial practice as well as in technical sales and consulting. So nothing stands in the way of a seamless implementation of WERKLICHT into your existing production environment.

EXTEND3D Headquarter

Part of Atlas Copco Group

81829 Munich

Wamslerstrasse 2

ipg-info@atlascopco.com

+49 (0)89 960 98 50 0

www.extend3d.com